Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performance Evaluation of Self-Compacting Concrete using PPC and Flyash

Authors: Lavudya Nikhitha Chowhan, Yerikam Yamuna, Dr. M. Swaroopa Rani

DOI Link: https://doi.org/10.22214/ijraset.2024.65722

Certificate: View Certificate

Abstract

India, as the world\'s second-largest consumer of concrete, faces an urgent need for sustainable construction practices to address the environmental challenges of cement production and its eventual scarcity. This research investigates the effect of fly ash (FA) as a partial replacement for cement in self-compacting concrete (SCC) across various grades (M30, M50, M70), focusing on both fresh and hardened properties. The study explores the impact of fly ash content (ranging from 0% to 50%) on workability, compressive strength, split tensile strength, and flexural strength. Fresh properties were evaluated through slump flow, V-funnel, L-box, and J-ring tests, demonstrating that fly ash enhances flowability, passing ability, and filling ability up to 30% replacement. However, higher FA content negatively impacted the fresh properties, particularly in lower-grade mixes. In terms of hardened properties, compressive, split tensile, and flexural strengths improved up to 20-30% fly ash, attributed to its pozzolanic reaction and better particle packing. Beyond these levels, strength reduced due to increased paste viscosity and cement dilution. Overall, the research emphasizes the need for optimal fly ash content to maximize strength, workability, and durability in SCC applications.

Introduction

I. INTRODUCTION

Self-Compacting Concrete (SCC), also known as self-consolidating concrete, is a highly fluid and workable type of concrete that fills formwork effortlessly, eliminating the need for mechanical vibration. Unlike traditional concrete, which can segregate during placement, SCC maintains uniformity by flowing and distributing evenly under its own weight. Its enhanced flowability does not compromise its durability or strength, making it a robust material for construction. To prevent issues like bleeding and segregation, SCC formulations include admixtures such as superplasticizers and viscosity-modifying agents (VMAs), ensuring stability and preventing weaknesses or surface imperfections. SCC formulations often incorporate supplementary cementitious materials (SCMs) such as fly ash, bagasse ash, and ground granulated blast furnace slag (GGBS) to enhance performance and promote sustainability. Among these, fly ash, a byproduct of coal-fired thermal power plants, is a traditional yet crucial SCM. Its use addresses environmental concerns by converting waste into a resource while improving SCC's workability, reducing the heat of hydration, and enhancing long-term strength through pozzolanic reactions.

As cement is a non-renewable resource, there is a growing need to replace it with more sustainable alternatives. In earlier practices, Portland-Pozzolana Cement (PPC), which contains 20–30% fly ash, was widely adopted to reduce cement consumption. However, limited studies have focused on developing SCC using PPC in combination with additional fly ash as an SCM. In this study, an attempt is made to explore the characteristics of SCC developed with PPC and up to 50% replacement of PPC by additional fly ash, providing insights into a sustainable and efficient concrete formulation.

II. CURRENT TRENDS AND RESEARCH DIRECTIONS

Research on Self-Compacting Concrete (SCC) incorporating supplementary cementitious materials (SCMs) such as fly ash (FA) and ground granulated blast furnace slag (GGBFS) has evolved over the years, highlighting their significant role in improving performance and sustainability. Early studies, such as those by N. Bouzoubaâa and M. Lachemi (2001), showed that high volumes of Class F fly ash could enhance SCC's fluidity and cohesiveness, providing acceptable workability and mechanical properties at replacement levels of up to 60% [1]. Research by J M Khatib (2008) further demonstrated that high-volume FA (up to 80%) could reduce shrinkage and improve durability, despite a slight increase in absorption with higher FA content [2]. In the following years, studies began to refine the optimal use of FA in SCC mixes. For example, P. Dinakar et al. (2013) found that fly ash replacement levels between 10–70% in Portland Pozzolana Cement (PPC) mixes resulted in optimal strength and durability at 30–50% FA replacement [3].

In 2016, M. Arun Kumar et al. showed that incorporating a combination of FA and GGBFS (30% replacement) in SCC resulted in minimal differences in workability and strength compared to conventional mixes, with a 50:50 blend providing the best balance for sustainable, durable construction [4]. Meanwhile, research by Mohd. Asif et al. (2017) indicated that mixes with up to 35% FA performed well, with OPC mixes containing 15% FA achieving the best strength results [5]. More recent investigations, such as those by M. Solikin and T. Mulyanto (2020), found that high-volume fly ash SCC provided good compressive strength at 56 days but exhibited lower flexural strength [6]. Other studies, like those by Nisheeth Agnihotri et al. (2021), emphasized the improvement in rheological and mechanical properties of SCC when FA was combined with superplasticizers [7]. The potential for further enhancement was noted in 2023, with Sami Hijah et al. highlighting the positive impact of basalt fibers on SCC mixes incorporating fly ash, resulting in better workability and mechanical properties [8]. More recent studies, such as those by C. Praneeth Sudharsan et al. (2022), confirmed that partial cement replacement with FA and GGBFS improved mechanical performance, including tensile strength, across multiple SCC grades, contributing to more sustainable concrete solutions [9]. Finally, research by Navdeep Singh et al. (2019) explored the use of High-Volume Fly Ash (HVFA) based SCC incorporating recycled concrete aggregates (RCA) and Coal Bottom Ash (CBA), showing that while early-age strengths may decrease with higher FA content, long-term performance improved significantly, particularly when supplemented with materials like metakaolin [10]. Collectively, these studies underscore the importance of SCMs, particularly fly ash and GGBFS, in advancing sustainable, high-performance SCC.

III. EXPERIMENTAL METHODOLOGY

A. Brief Outline Of The Study

This study explores the benefits of incorporating fly ash into self-compacting concrete (SCC), using Portland Pozzolana Cement (PPC) as a sustainable alternative to traditional cement. The primary objective is to determine the optimal dosage of fly ash that can replace PPC while maintaining or enhancing both mechanical and self-compacting properties of the concrete.

Several attempts have been made by researchers in the past to establish mix designs for SCC with the addition of fly ash. The current study adopted the guidelines of IS 10262:2019 [11] for the mix design of self-compacting concrete, as well as the design approach suggested by P. Dinakar (2012) [12], which includes varying fly ash replacement levels from 0% to 50% of PPC. The research aims to assess whether the addition of fly ash affects the self-compacting properties of the concrete, particularly its flowability, stability, and uniformity. Specifically, the study investigates if the concrete retains its ability to compact under its own weight upon increasing the fly ash content.

The study focuses on three concrete grades: M30, M50, and M70. Three distinct mixes with 5 varying flyash contents from 10 to 50% are prepared, cured, and tested for both fresh and mechanical properties. The fresh properties will be examined to verify self-compactability, while mechanical properties (such as compressive, tensile, and flexural strength) will be tested to understand the impact of varying fly ash dosages on concrete performance. Additionally, the study will investigate the effects of high fly ash dosages on self-compacting ability, considering that PPC already contains 20-30% fly ash. Ultimately, the aim is to identify the optimum fly ash dosage for each grade of concrete that maximizes both mechanical performance and self-compacting properties.

B. Materials Selection And Characteristics

1) Cement, Flyash and Aggregates

The materials used in this study include UltraTech Portland Pozzolana Cement, a high-quality binder sourced from a single supplier. Locally available Godavari River sand confining to Zone-II, and 10mm - 12mm crushed stone is used as Coarse aggregate selected for its strength and durability. Class F Fly ash, obtained from NTPC Simhadri, is added to enhance concrete's workability, durability, and strength while reducing cement usage. Potable water, with IS standards and free from impurities is used for mixing and curing. Table I provides details about the materials utilized in this study.

TABLE I Physical properties of cement and Flyash

|

Sl.No |

Property |

Cement |

FA |

|

1. |

Fineness |

6% |

10% |

|

2. |

Standard Consistency |

35% |

26% |

|

3. |

Initial Setting Time |

60 min |

30 min |

|

4. |

Final Setting Time |

292 min |

600 min |

|

5. |

Compressive Strength |

48 MPa |

25 MPa |

|

6. |

Specific Gravity |

2.88 |

2.2 |

The following Table II presents the chemical compositions of cement and fly ash, detailing the proportions of key oxides such as silica (SiO?), alumina (Al?O?), iron oxide (Fe?O?), calcium oxide (CaO), and magnesium oxide (MgO). These values highlight the variations in chemical content between the two materials, which influence their performance and reactivity in cementitious applications.

TABLE III

Comparison of Chemical properties of Cement and Flyash

|

Sl. No |

Characteristics |

Cement (%) |

FA (%) |

|

1. |

Lime (CaO) |

43.33 |

1.7 |

|

2. |

Silica (SiO2) |

33.72 |

62.5 |

|

3. |

Alumina (Al2O3) |

10.44 |

26.2 |

|

4. |

Iron oxide (Fe2O3) |

4.93 |

4.2 |

|

5. |

Magnesia (MgO) |

0.73 |

0.8 |

|

6. |

Sulphur trioxide (SO3) |

2.28 |

0.25 |

The Table III outlines the various tests conducted to evaluate the physical properties of the coarse aggregates used in the study. These tests provide crucial insights into the quality, durability, and suitability of the aggregates for use in concrete.

TABLE IIIII

Tests on Fine Aggregates and Coarse Aggregates.

|

Test |

Physical Properties of Fine Aggregates |

Physical Properties of Coarse Aggregates |

|

Specific gravity |

2.70 |

2.625 |

|

Bulk density (Loose), kg/ m3 |

1492 |

1386 |

|

Bulk density (compacted) kg/ m3 |

1620 |

1460 |

|

% Water absorption |

1.1 |

0.50 |

|

Fineness modulus |

2.678 |

6.62 |

2) Chemical Admixture

Auramix 400, a polycarboxylate ether-based superplasticizer, enhances concrete workability, strength, and durability by reducing water content. Suitable for high-strength, self-consolidating, and ready-mix concrete, it complies with industry standards and offers compatibility with various cements and admixtures.

3) Viscosity Modifying Agent (VMA)

Viscosity Modifying Admixtures (VMAs) control concrete viscosity, preventing segregation and ensuring optimal flow, particularly in self-compacting concrete (SCC). They enhance durability and performance, making them essential for precise flow adjustment in high-performance mixes.

C. Mix Proportions

A total of 18 mixes were used to examine the properties of self-compacting concrete (SCC) with and without fly ash (FA). Both fresh and mechanical properties were investigated, and the details of the High Volume Flyash Self Compacting Concrete (HVFSCC) mixes are provided in Table 2. These proportions were determined after conducting several trial mixes. Mixes A0, B0, and C0 are the control mixes, while mixes A1-A5, B1-B5, and C1-C5 incorporate fly ash at replacement levels ranging from 10% to 50% for M30, M50, and M70 grades of SCC, respectively.

Table III

Mix Proportions per 1m3 of Concrete

|

Mix Id |

Grade of Concrete (Mpa) |

TCM (Kg/m3) |

Water/Cement Ratio |

Flyash (%) |

Cement (Kg/m3) |

Flyash (Kg/m3) |

Coarse Aggregate (Kg/m3) |

Fine Aggregate (Kg/m3) |

Water (Kg/m3) |

VMA (%) |

Superplasticizer (%) |

|

A0 |

M30 |

450 |

0.54 |

0 |

450 |

0 |

846 |

875 |

185 |

0 |

0.6 |

|

A1 |

450 |

10 |

405 |

45 |

846 |

875 |

175 |

0.3 |

0.8 |

||

|

A2 |

450 |

20 |

360 |

90 |

846 |

875 |

175 |

0.8 |

|||

|

A3 |

450 |

30 |

315 |

135 |

846 |

875 |

170 |

1 |

|||

|

A4 |

450 |

40 |

270 |

180 |

846 |

875 |

165 |

1.1 |

|||

|

A5 |

450 |

50 |

225 |

225 |

846 |

875 |

162 |

1.2 |

|||

|

B0 |

M50 |

500 |

0.42 |

0 |

500 |

0 |

709 |

900 |

185 |

0 |

0.6 |

|

B1 |

500 |

10 |

450 |

50 |

709 |

900 |

164 |

0.2 |

0.8 |

||

|

B2 |

500 |

20 |

400 |

100 |

709 |

900 |

160 |

1 |

|||

|

B3 |

500 |

30 |

350 |

150 |

709 |

900 |

155 |

1.2 |

|||

|

B4 |

500 |

40 |

300 |

200 |

709 |

900 |

155 |

1.2 |

|||

|

B5 |

500 |

50 |

250 |

250 |

709 |

900 |

152 |

1.3 |

|||

|

C0 |

M70 |

550 |

0.32 |

0 |

550 |

0 |

745 |

820 |

160 |

0 |

0.6 |

|

C1 |

550 |

10 |

495 |

55 |

745 |

820 |

137 |

0.2 |

1 |

||

|

C2 |

550 |

20 |

440 |

110 |

745 |

820 |

135 |

1.1 |

|||

|

C3 |

550 |

30 |

385 |

165 |

745 |

820 |

130 |

1.2 |

|||

|

C4 |

550 |

40 |

330 |

220 |

745 |

820 |

126 |

1.4 |

|||

|

C5 |

550 |

50 |

275 |

275 |

745 |

820 |

126 |

1.4 |

|||

|

* Water and superplasticizer dosage for each mix is adjusted at the time of mix accordingly * A0, B0 and C0 are the control mixes for M30, M50 and M70 grades of SCC respectively. |

|||||||||||

IV. EXPERIMENTAL INVESTIGATIONS AND OUTCOMES

The experimental program includes reaching out to the optimal dosage of flyash for M30, M50 and M70 grade HVFSCC.

A. Fresh properties of High Volume Flyash Self Compacting Concrete

The standard workability tests for conventional concrete are insufficient for self-compacting concrete (SCC) as they fail to capture all its characteristics. Therefore, various specialized test methods have been developed to evaluate the workability of SCC. However no single test method can yet assess all relevant aspects of SCC's workability. The Slump cone test, V funnel test, L box test and the J ring test were conducted following the EFNARC guidelines as shown in Fig.1 below.

Fig.1 Performing Fresh properties of HVFSCC

The slump flow test evaluates the flowability of self-compacting concrete by measuring the spread diameter after lifting the cone. The V-funnel test assesses viscosity and filling ability based on flow time. The L-box test measures the passing ability through reinforcement and the height ratio after flow, while the J-ring test evaluates passing ability and flow spread around obstacles. These tests were performed on all mixes, and the results are summarized in Table IV.

TABLE IVV

Fresh Properties of HVFSCC

|

Sl. No |

% of Flyash |

Slump Test (Flow in mm) |

V Funnel Test (Time in s) |

L Box Test (Δh in mm) |

J Ring Test (Flow in mm) |

||||||||

|

M30 |

M50 |

M70 |

M30 |

M50 |

M70 |

M30 |

M50 |

M70 |

M30 |

M50 |

M70 |

||

|

1 |

0 |

643 |

650 |

675 |

13 |

12 |

8 |

0.93 |

0.82 |

0.83 |

638 |

615 |

630 |

|

2 |

10 |

660 |

690 |

700 |

10 |

13 |

9 |

0.95 |

0.86 |

0.89 |

651 |

620 |

630 |

|

3 |

20 |

680 |

710 |

720 |

9 |

11 |

11 |

0.96 |

0.88 |

0.97 |

676 |

645 |

650 |

|

4 |

30 |

700 |

680 |

680 |

7.5 |

15 |

13 |

0.97 |

0.81 |

0.85 |

684 |

655 |

640 |

|

5 |

40 |

660 |

670 |

650 |

11 |

13 |

12 |

0.89 |

0.78 |

0.81 |

700 |

625 |

660 |

|

6 |

50 |

650 |

660 |

690 |

9 |

14 |

15 |

0.88 |

0.93 |

0.77 |

650 |

630 |

690 |

The results demonstrate that the fresh properties of self-compacting concrete (SCC) are significantly influenced by fly ash (FA) replacement, driven by its impact on mix composition and particle packing. Slump flow improves with FA addition up to 30% due to the spherical particles of FA enhancing lubrication and reducing internal friction. However, higher FA content reduces flowability for certain grades, likely due to increased paste viscosity, though higher cementitious content in some mixes mitigates this effect.

The V-funnel test highlights improved filling ability up to 30% FA, while higher FA levels increase resistance to flow due to the addition of fines. Similarly, L-box and J-ring test results show optimal passing ability and flow spreads at moderate FA levels, with excessive FA content reducing cohesion and increasing viscosity, leading to diminished performance. These findings emphasize the importance of optimizing FA replacement to balance workability, reduce viscosity, and maintain good segregation resistance.

???????B. Hardened properties of High Volume Flyash Self Compacting Concrete

To accurately evaluate SCC's mechanical performance, tests such as compressive strength, split tensile strength, and flexural strength are essential. These tests provide insights into SCC's load-bearing capacity, durability, and resistance to deformation, which are critical for its application in various structural scenarios. The mechanical property tests were conducted as per relevant Indian standards, with detailed results presented in the following sections as shown in Fig. 2.

Fig.2 Performing hardened tests on HVFSCC Specimens

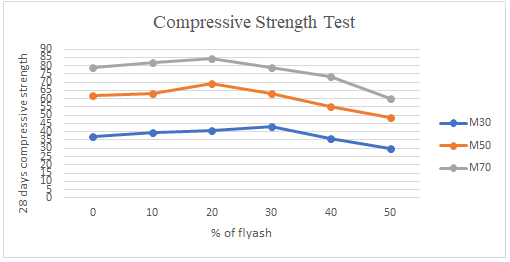

C. Compressive Strength

The compressive strength of self-compacting concrete (SCC) is a measure of its capacity to resist axial loads without failure. It is typically determined at 28 days using standard 150×150×150 mm cubic specimens, following the guidelines of IS 516 (1959)

[13]. A total of 18 specimens, divided into three sets, were prepared with varying fly ash content ranging from 10% to 50%, along with control mixes for M30, M50, and M70 grades of concrete. After 28 days of curing, the specimens were tested using a compression testing machine to identify the optimum fly ash dosage, with the results presented in the following graph.

Fig.3 Compressive Strength test results of HVFSCC

The compressive strength results from Fig.3 show significant variations with fly ash replacement, influenced by its impact on the binder matrix and particle packing. For M30, strength increases up to 30% fly ash (16.56% higher than the control mix) due to enhanced pozzolanic reactions and packing density but decreases beyond 30%, with a 19.35% drop at 50% fly ash, likely from increased porosity. M50 shows the highest strength at 20% fly ash (11.13% increase), attributed to improved particle dispersion, while higher replacements reduce strength by up to 21.46% at 50%, due to cement dilution.

For M70, maximum strength occurs at 20% fly ash (6.51% higher), as fly ash utilization complements the high cementitious content. However, further replacement decreases strength, with a 23.69% drop at 50%, caused by slower strength gain and increased voids. These results highlight the need for optimal fly ash replacement to maximize strength while minimizing adverse effects.

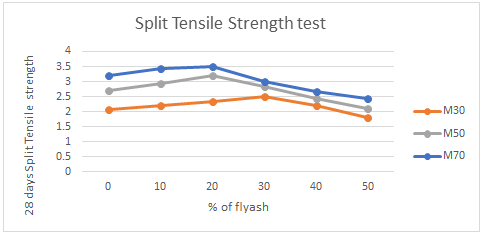

2) Split Tensile Strength

The split tensile strength test of SCC evaluates its resistance to tensile stresses, measured indirectly by applying a diametral compressive load. The test was conducted on 18 cylindrical specimens (150 mm in diameter and 300 mm in length) for each grade of concrete (M30, M50, and M70), in accordance with the guidelines specified in IS 5816 (1999) [14].

Fig.4 Split Tensile Strength test results of HVFSCC

The above Fig.4 illustrate the average 28-day Split Tensile strength of SCC specimens for various mixes with differing percentages of fly ash (FA).

The split tensile strength results show that fly ash (FA) significantly affects SCC performance. In M30, strength increases by 6.7%, 12.9%, and 20.2% at 10%, 20%, and 30% FA, respectively, due to improved particle packing and pozzolanic activity. However, at 40% and 50% FA, strength decreases by 5.7% and 12.5% due to insufficient cementitious material.

For M50, strength peaks at 20% FA with an 18.1% increase, while higher FA levels reduce strength by up to 22.5%, attributed to reduced binder content. In M70, strength improves by 7.5% and 9.7% at 10% and 20% FA but declines at 30% FA and beyond due to increased paste viscosity and delayed strength gain. These results emphasize the importance of optimal FA levels for tensile strength. This reduction in strength at higher fly ash content is attributed to reduced cement content and lower C3A levels, which are critical for early strength development.

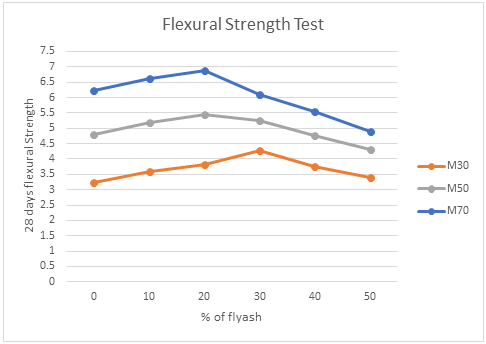

3) Flexural Strength

The flexural strength test of concrete evaluates its ability to resist bending stresses and is typically conducted using beams subjected to a two-point loading system. This test provides essential information on the concrete's performance under load in structural applications, in accordance with IS 516: 1959 [13]. In the current study, beams with dimensions of 750 mm × 150 mm × 150 mm were cast and tested for each varying fly ash content across different grades of concrete.

???????

???????

Fig.5 Flexural Strength Test Results of HVFSCC

The above Fig.5 illustrate the average 28-day Flexural strength of SCC specimens for various mixes with differing percentages of fly ash (FA).

For M30, M50, and M70, the flexural strength increases initially with the addition of fly ash up to 20%. Specifically, at 10% fly ash, M30, M50, and M70 show increases of 11.4%, 8.6%, and 6.4%, respectively, compared to the control mix (0% fly ash). At 20% fly ash, the flexural strength improves further by 18.2%, 14.0%, and 10.6% for M30, M50, and M70, respectively. This enhancement is due to the pozzolanic effect of fly ash, which contributes to better hydration and bond formation, improving overall strength. However, beyond 20% fly ash, the flexural strength starts to decrease. At 30% fly ash, M30 shows an increase of 32.9%, but M50 and M70 experience a slight drop in strength (down 1.0% and 11.1%, respectively). The decline at higher fly ash contents (40% and 50%) is attributed to reduced cement content and increased viscosity, which may hinder the strength development. At 50% fly ash, M30, M50, and M70 show reductions of 5.1%, 10.0%, and 21.3%, respectively, due to slower hydration and lower early strength gain.

Conclusion

Incorporating fly ash up to 30% significantly improves the fresh properties of self-compacting concrete (SCC), enhancing flowability, filling ability, and passing ability, as seen in slump flow, V-funnel, L-box, and J-ring tests. However, beyond 30%, higher paste viscosity and reduced cohesion negatively affect these properties, especially in lower-grade mixes like M30 and M50. Higher-grade mixes, such as M70, better tolerate higher fly ash contents due to their higher cementitious content. Strength tests show that compressive, split tensile, and flexural strengths improve with fly ash up to 20-30%, but decline beyond this level. M30 achieves peak compressive strength at 30% FA, while M50 and M70 peak at 20%, benefiting from fly ash’s pozzolanic effect. At higher FA contents, strength declines due to increased porosity, slower hydration, and reduced cement content. In conclusion, fly ash replacement should be optimized around 20-30% to maximize strength and workability while minimizing adverse effects like reduced early-age strength and increased porosity.

References

[1] N. Bouzoubaâ and M. Lachemi, “Self Compacting Concrete Incorporating High-Volumes of Class F Fly Ash: Preliminary Results,” 2001. [2] J. M. Khatib, “Performance of self-compacting concrete containing fly ash,” Constr Build Mater, vol. 22, no. 9, pp. 1963–1971, Sep. 2008, doi: 10.1016/j.conbuildmat.2007.07.011. [3] P. Dinakar, M. Kartik Reddy, and M. Sharma, “Behaviour of self compacting concrete using Portland pozzolana cement with different levels of fly ash,” Mater Des, vol. 46, pp. 609–616, Apr. 2013, doi: 10.1016/j.matdes.2012.11.015. [4] M. Arun Kumar, S. Vinodhkumar, P. Kulanthaivel, and K. Sampathkumar, “The Asian Review of Civil Engineering Study on Properties of SCC with Partial Replacement of Cement by GGBFS and Fly Ash,” 2016. [Online]. Available: www.trp.org.in [5] R. Mustafa and W. Akram, “ANALYSIS OF SELF-COMPACTING CONCRETE USING PPC AND OPC WITH DIFFERENT PROPORTIONS OF FLY ASH.” [6] M. Solikin and T. Mulyanto, “Mechanical properties of self-compacting concrete incorporated with high volume fly ash,” in IOP Conference Series: Materials Science and Engineering, Institute of Physics Publishing, May 2020. doi: 10.1088/1757-899X/821/1/012019. [7] N. Agnihotri, R. Agarwal, and U. S. Vidyarthi, “Experimental Study of Self Compacting Concrete using Portland Cement and Mineral Admixture,” 2021. [Online]. Available: www.ijisrt.com595 [8] E. Sami Hijah, O. Najm, and O. Mohamed, “Effect of basalt fiber on self-consolidating concrete with fly ash replacement,” Mater Today Proc, 2023, doi: https://doi.org/10.1016/j.matpr.2023.03.197. [9] C. P. Sudharsan, S. Gosh, and Dr. H. Sood, “Development of Self-Compacting Concrete of Grades M25, M30 and M35 Using Composite Cement,” Int J Res Appl Sci Eng Technol, vol. 10, no. 3, pp. 2010–2013, Mar. 2022, doi: 10.22214/ijraset.2022.41047. [10] N. Singh, P. Kumar, and P. Goyal, “Reviewing the behaviour of high volume fly ash based self compacting concrete,” Nov. 01, 2019, Elsevier Ltd. doi: 10.1016/j.jobe.2019.100882. [11] I. Standard, “oa QØhV feJ vuq ikru-ekxZ n’khZ fl¼ka r Concrete Mix Proportioning-Guidelines (Second Revision) Hkkjrh; ekud,” 2019. [Online]. Available: www.standardsbis.in [12] P. Dinakar, “Design of self-compacting concrete with fly ash,” Magazine of Concrete Research, vol. 64, no. 5, pp. 401–409, May 2012, doi: 10.1680/macr.10.00167. [13] B. of Indian Standards, “IS 516 (1959): Method of Tests for Strength of Concrete.” [14] B. of Indian Standards, “IS 5816 (1999): Method of Test Splitting Tensile Strength of Concrete.”

Copyright

Copyright © 2024 Lavudya Nikhitha Chowhan, Yerikam Yamuna, Dr. M. Swaroopa Rani. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65722

Publish Date : 2024-12-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online